Composite Lattice Prestressed Soffit Slab (CLPSS)

Description

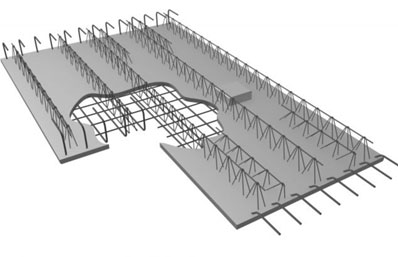

CLPSS are a prestressed prefab slab, consisting of high strength concrete, usually C45/55, and strands that are 70% prestressed, on top there is a thick reinforced cast in situ concrete layer. The main difference to the composite lattice prestressed soffit slabs is, apart from the thickness of the cast in situ layer, that during the building stage, the upper rebar is carrying like a truss. It is a slab made for shorter spans and is mostly used between 3 m and 9 m span. The advantage of the thick top layer is that the slab can easily be made continuous over the beams to reduce the deformations.

The fire resistance of CLPSS is around 60 min, depending on the thickness. This is lower than most of the concrete slabs, due to the combination of high strength concrete, prestressing on the bottom, where the fire normally acts, and relatively low height.

The flexibility on site is better than most prefab slab because of the thick cast in situ layer on top, the geometric flexibility is very low as for almost all prefab slabs. Building systems are somewhat integratable in the cast in situ layer but drilling a hole through a prestressed layer is not recommended, thus the database says that building systems are not integratable. The complexity of the fabrication is medium, the geometry is simple, but it involves prestressing and the upper rebars sticking out also complicates the production. On site it is easy to use, because it acts a lost formwork and the upper rebars are already in the right place, there is also less propping required than with ordinary formwork due to the upper rebars acting as a truss.

As in most concrete floors, vibration is not a concern due to the large weight.

The slenderness is considerably lower than for the Composite solid prestressed soffit slabs because lower strength material is used and there is less prestressing. For residential buildings with 3kPa characteristic load, a slenderness of l/h=30 can be achieved, for office buildings with a characteristic load of 4kPa, the slenderness is a bit lower with l/h=28.

Database

Floor type |

Composite Lattice Prestressed Soffit Slabs |

||

|---|---|---|---|

Materials |

concrete C45/55 precast_concrete C30/37 in situ_reinforcing steel 500N/mm^2 |

||

Description |

precast slab with upper rebars carrying as truss in buiding stage |

||

Way of carrying |

Does the main span carry in one or two directions? |

one way slab |

|

Span width low [m] |

Economically possible |

3 |

|

Span width high [m] |

Economically possible |

9 |

|

Additional measures when installing |

propping up_Cranage |

||

Prefab? |

Is prefab possible? |

yes |

|

Continous slab? |

Can you build the slab with supports in middle of the slab? |

yes |

|

Building systems integratable? |

Can buildings systems be included into the slab itself? |

no |

|

Fire |

Fireresistance without costly measures [min] |

60 |

|

Substructure |

Certain prerequisites necessary? |

yes |

|

Prone to vibration |

no |

||

Environment |

General classification including formwork |

1 to 5 terrible to very good |

3 |

Construction time |

Time on site |

1 to 5 very slow to very fast |

3 |

Flexibility |

Average of the next two |

1 to 5 |

2 |

Flexibility on site |

How flexible is the system to spontaneous changes on site? |

1 to 5 terrible to very good |

3 |

Flexibility geometry |

How good can you adapt the slab to complex geometries? |

1 to 5 not at all to very easy |

1 |

Complexity |

Average of the next two |

1 to 5 |

3.5 |

Complexity fabrication |

Complexity of floor itself. |

1 to 5 very complicated to very simple |

3 |

Complexity installation |

Complexity installation on site |

1 to 5 very complicated to very simple |

4 |

Slenderness l/h 3kPa |

Applied load (without selfweight) |

Residential building |

30 |

Slenderness l/h 4kPa |

Applied load (without selfweight) |

Office building |

28 |

Weight [kN/m3] |

per m2 and total height of slab |

25 |

|

Embodied energy [MJ/m3] |

per m2 and total height of slab |

6291 |

References

- General information:

Goodchild, C., Webster, R., & Elliott, K. (2009). Economic Concrete Fram Elements to Eurocode 2. Camberley UK: The Concrete Centre.

http://www.lastrepredalle.it/

https://documents.pub/document/349-0-nl-pekso-precast-plate-flooring-2013-lr-1.html- Span width:

3 - 9m (Goodchild, C., Webster, R., & Elliott, K. (2009). Economic Concrete Fram Elements to Eurocode 2. Camberley UK: The Concrete Centre.)

4 - 7m (https://ms-element.ch/wp-content/uploads/2018/05/Prospekt_Doppelwand_und_Deckensysteme.pdf)- Fire resistance:

60min (Goodchild, C., Webster, R., & Elliott, K. (2009). Economic Concrete Fram Elements to Eurocode 2. Camberley UK: The Concrete Centre.)

60min (https://documents.pub/document/349-0-nl-pekso-precast-plate-flooring-2013-lr-1.html)- Slenderness:

l/h=30 for 3kPa, l/h=28 for 4kPa (Goodchild, C., Webster, R., & Elliott, K. (2009). Economic Concrete Fram Elements to Eurocode 2. Camberley UK: The Concrete Centre.)

- Weight:

- Embodied energy:

- Photo Source:

https://www.ultraspan.ca/prestressed-filigree-slab-vs-hollowcore/