Steel-Concrete Composite Slab

Description

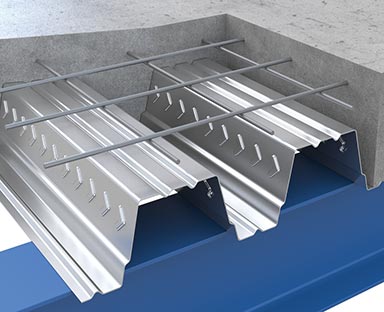

Steel-concrete composite slab consist of steel profiles, usually and I- or H-profiles, steel decking acting a lost formwork and cast in situ reinforced concrete on top. The concrete quality is usually around C30/37, but it can go from C20/25 up to C50/60. The concrete is connected to the steel beams using shear studs. The steel decking is oriented perpendicular to the steel beams so the force can be introduced better into the steel and so the decking can stand without support during construction. For that the steel beams need to be about 3 to 4 m apart from each other. The economical span lays between 4 and 10 m, which is the typical span in European office buildings, this is also where they are typically used. Steel-concrete composite slab can be easily made continuous by putting more rebars in the concrete above the beam to increase the resistance against negative moments.

Steel-concrete composite slabs do not perform well during fires, because the steel beams lose their loading capacity fast without protection. Usually, 60 minutes can be achieved without much effort.

The flexibility on site is average due to cast in situ concrete and all the components being installed after each other. This leaves options for spontaneous adaptation. The flexibility in geometry is rather bad due to the steel decking dictating the direction of the force flow, thus not allowing for openings. Building systems cannot be integrated into the slab but can be put between the steel beams, all the necessary cables and tubes are not blocked by the steel beams, because it is statically no problem to put holes in the webs of the steel beams. The complexity in fabrication and installation is also average which is quite good for a non-prefab slab, but that is mainly because the steel profiles are prefabricated, the steel decking acting as lost formwork also helps. All the connections to the beams and columns can be made in steel which is also a plus. The construction time is average because the steel profiles and the decking are quickly installed, however, the concrete takes some time to cure. This can slow down construction heavily, especially if one decides to prop up the steel profiles to decrease the stress in them.

The concrete layer is usually thick enough that vibration is not a problem.

The slenderness typically lays around l/h=20, which is on the low end. But the ability to put building systems between the steel profiles make steel-concrete composite slabs highly competitive in office buildings, where lots of building systems are required and high building speed is required.

Database

Floor type |

Steel-Concrete Composite Slab |

||

|---|---|---|---|

Materials |

concrete (from C20/25 to C50/60 possible)_structural steel_reinforcing steel_steel decking |

||

Description |

steel beam carrying steeldecking that acts as lost formwork for in sito concrete slab above |

||

Way of carrying |

Does the main span carry in one or two directions? |

one way slab |

|

Span width low [m] |

Economically possible |

4 |

|

Span width high [m] |

Economically possible |

10 |

|

Additional measures when installing |

decking_shear stud_maybe propping |

||

Prefab? |

Is prefab possible? |

yes/no |

|

Continous slab? |

Can you build the slab with supports in middle of the slab? |

yes |

|

Building systems integratable? |

Can buildings systems be included into the slab itself? |

yes |

|

Fire |

Fireresistance without costly measures [min] |

60 |

|

Substructure |

Certain prerequisites necessary? |

no |

|

Prone to vibration |

no |

||

Environment |

General classification including formwork |

1 to 5 terrible to very good |

2 |

Construction time |

Time on site |

1 to 5 very slow to very fast |

3 |

Flexibility |

Average of the next two |

1 to 5 |

2.5 |

Flexibility on site |

How flexible is the system to spontaneous changes on site? |

1 to 5 terrible to very good |

3 |

Flexibility geometry |

How good can you adapt the slab to complex geometries? |

1 to 5 not at all to very easy |

2 |

Complexity |

Average of the next two |

1 to 5 |

3 |

Complexity fabrication |

Complexity of floor itself. |

1 to 5 very complicated to very simple |

3 |

Complexity installation |

Complexity installation on site |

1 to 5 very complicated to very simple |

3 |

Slenderness l/h 3kPa |

Applied load (without selfweight) |

Residential building |

20 |

Slenderness l/h 4kPa |

Applied load (without selfweight) |

Office building |

20 |

Weight [kN/m3] |

per m2 and total height of slab |

7.5 |

|

Embodied energy [MJ/m3] |

per m2 and total height of slab |

4400 |

References

- General information:

Lecture Stahlbau III. ETH Zürich.

- Span width:

3 - 8m (https://constructalia.arcelormittal.com/files/AMC_floors_guide_EN_June2019_LR–b47b21285b39514432cf4da5d75b23f1.PDF)

6 - 12m (https://www.szs.ch/wp-content/uploads/2017/08/2014-01-02_02_d_Stahldeckensysteme.pdf)- Fire resistance:

30min without additional measures, 60min with some measures (https://www.sciencedirect.com/science/article/abs/pii/0143974X9400015A#:~:text=During%20fire%20the%20sheeting%20heats,is%20at%20least%2030%20minutes.)

30min with concrete thickness up to 6cm, 60min if thicker (https://www.steelconstruction.info/Design_of_composite_steel_deck_floors_for_fire)- Slenderness:

l/h=19 for 3kPa, l/h=19 for 4kPa (Lecture Stahlbau III ETH Zurich)

- Weight:

- Embodied energy:

- Photo Source:

https://www.rudolf-hensel.de/produkte/hensotherm-820-ks-brandschutz-fuer-beton/