Slim-Floor

Description

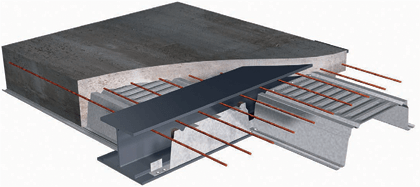

Slim floors are like the steel-concrete composite slabs. They both use steel profiles to carry the load to the beams, both introduce the load into the steel profiles, usually HEA and sometimes IPE, with a steel decking covered by reinforced concrete. The main difference is that the steel profile in slim floors is not below the steel decking but on the same level as the steel decking. Normally there is a steel plate welt on the bottom of the steel profile creating a big lower flange to attach the steel decking to. There are also steel profiles with a wider lower flange specifically made for slim floors. The concrete layer usually goes above the steel profile to have continuous reinforcement over the profiles. Often there are holes in the steel profile to connect the lower reinforcement layer through to also make that layer continuous. There are various variations on how to create the slab between the steel profiles, some involve using hollow core elements instead of steel decking with cast in situ concrete above. This accelerates the building process and allows for bigger distances between the steel profiles at the cost of flexibility and usually a higher price. The economic span width lays between 6 and 13 m. Slim floors can be installed continuous to reduce deformations, but one must remember to reinforce the upper flange and concrete layer accordingly over the beam.

Slim floors do not perform well against fire, due to the high reliance on steel profiles, but can reach 60 min without fire protection panels, because the surrounding concrete has a cooling effect on the steel.

The flexibility on site is slightly more limited than for steel-concrete composite slabs, because in slim floors the steel profiles are not separated from the concrete, so there is less room for spontaneous changes. The geometric flexibility is rather bad due to the steel decking dictating the direction of the force flow, thus not allowing for openings, the flexibility gets even worse when using hollow core elements. A big downside when compared to the steel-concrete composite slabs is that the integration of building systems is not possible in slim floors. The complexity is medium and significantly lower when using hollow core elements. The construction time is basically the same as in steel-concrete composite slabs, because the building process is also the same when using steel decking. With hollow core elements, the construction time decreases significantly.

The mass is usually high enough for vibration not to be a problem.

The slenderness typically lays around l/h=25, this is the big advantage of the slim floor when compared to the steel-concrete composite slab, where the slenderness only reaches l/h=20. This is the result of putting the concrete on the same level as the steel profile. However, when many building systems have to be installed, the steel-concrete composite slab is overall the more slender option.

Database

Floor type |

Slim-Floor |

||

|---|---|---|---|

Materials |

concrete_steel beam_steel decking_reinforcing steel |

||

Description |

steel beam integrated into concrete slab steeldecking as lost formwork |

||

Way of carrying |

Does the main span carry in one or two directions? |

one way slab |

|

Span width low [m] |

Economically possible |

6 |

|

Span width high [m] |

Economically possible |

13 |

|

Additional measures when installing |

cranage |

||

Prefab? |

Is prefab possible? |

no |

|

Continous slab? |

Can you build the slab with supports in middle of the slab? |

yes |

|

Building systems integratable? |

Can buildings systems be included into the slab itself? |

no |

|

Fire |

Fireresistance without costly measures [min] |

60 |

|

Substructure |

Certain prerequisites necessary? |

no |

|

Prone to vibration |

no |

||

Environment |

General classification including formwork |

1 to 5 terrible to very good |

2 |

Construction time |

Time on site |

1 to 5 very slow to very fast |

3 |

Flexibility |

Average of the next two |

1 to 5 |

3 |

Flexibility on site |

How flexible is the system to spontaneous changes on site? |

1 to 5 terrible to very good |

3 |

Flexibility geometry |

How good can you adapt the slab to complex geometries? |

1 to 5 not at all to very easy |

3 |

Complexity |

Average of the next two |

1 to 5 |

3 |

Complexity fabrication |

Complexity of floor itself. |

1 to 5 very complicated to very simple |

3 |

Complexity installation |

Complexity installation on site |

1 to 5 very complicated to very simple |

3 |

Slenderness l/h 3kPa |

Applied load (without selfweight) |

Residential building |

25 |

Slenderness l/h 4kPa |

Applied load (without selfweight) |

Office building |

25 |

Weight [kN/m3] |

per m2 and total height of slab |

18 |

|

Embodied energy [MJ/m3] |

per m2 and total height of slab |

5948 |

References

- General information:

https://sections.arcelormittal.com/repository2/Sections/5_5_2_SlimFloor.pdf

https://constructalia.arcelormittal.com/files/5_5_1_SlimFloor–e6ed7ccc7e15ff8fbb6a29eb8ce82342.pdf- Span width:

5 - 12m (https://sections.arcelormittal.com/repository2/Sections/5_5_2_SlimFloor.pdf)

6 - 14m (https://docplayer.org/3093423-Slim-floor-verbundtraeger-fuer-grosse-spannweiten-cosfb.html)

up to 14m (https://constructalia.arcelormittal.com/files/5_5_1_SlimFloor–e6ed7ccc7e15ff8fbb6a29eb8ce82342.pdf)

6 - 12m (https://bauforumstahl.de/upload/documents/publikationen/Bemessungshilfe_Deckentrager_neu.pdf)- Fire resistance:

60min (https://sections.arcelormittal.com/repository2/Sections/5_5_2_SlimFloor.pdf)

60min (http://lib.tkk.fi/Diss/2000/isbn9512252708/article3.pdf)

60min (https://fielders.com.au/products/flooring-solutions/slimflor-flooring/)- Slenderness:

Regular: l/h=25 for 3kPa, l/h=25 for 4kPa.(https://constructalia.arcelormittal.com/files/5_5_1_SlimFloor–e6ed7ccc7e15ff8fbb6a29eb8ce82342.pdf)

- Weight:

- Embodied energy:

- Photo Source:

https://architecturemagazine.co.uk/2013/11/13/high-performance-slim-floor-construction/